India's leading material handling system provider. Smarter & faster material handling system solutions provider. Armstrong's

"Armstrong is a leading & India's best warehouse automation company and Intralogistics & Warehouse Automation Solution provider that solves your complex problems with innovative know-how, hardware and software. Our intuitive solutions, precisely aimed at achieving operational efficacy, high visibility and space utilization, effort reduction with lowest TCO, make your operations Faster, Smarter & Cheaper.

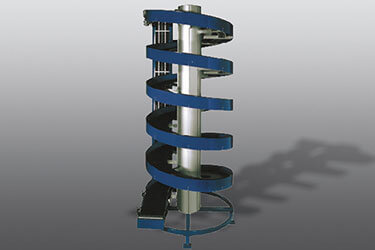

Armstrong's brilliant track record and a global footprint makes it India's best warehouse automation companies. Armstrong with its transformational Industry-4.0/IIOT compliant solutions, such as Receiving, Palletising, AS/RS (Automated Storage and Retrieval System), Sorting & Dispatch Management helps organizations achieve high productivity. As the machine runs & learns, our AI & Analytic algorithms improve the performance of the systems as they analyze the data generated by the second.

Our deep industry know-how & decades of experience helps leading companies in FMCG, Food, E-tail, Parcel & Courier, Retail & Warehousing industries to zip their costs. Our state-of-the-art manufacturing facilities, global service network and team of diverse & committed professionals ensure world-class delivery an d life cycle support."